Yahagi Industries’ Manufacturing

Head Office Plant

7-2 Hirokute-cho, Toyota City, Aichi Prefecture 471-0036

The plant was completed in 1964 and started operation as the headquarters the following year. It produces parts that are ready to be assembled into vehicles. The plant is divided into a fluororesin coating department mainly for engine parts and a resin molding department for engine areas, and also manufactures mass-produced products called small-volume products. It also serves as a shipping base for products from the Mifune and Fujioka plants to their destinations.

Resin

Fluorine Coating

Using a robot called COBOTTA, the trajectory is commanded by computer, and the parts are set.

Resin mold maintenance. Frequent removal of accumulated impurities due to air entry, improve the precision of the parts.

Heat is a key factor in resin molding, so temperature control is specific, and timing, such as the speed of injection, is also regulated.

Spray Painting. Painting that cannot be done by machines or assembly line work is still done by hand.

Appearance inspection machine work. Painting done on the conveyor belt is checked and scrutinized using a camera.

The undercover is assembled using a jig, a support device that facilitates each parts’ fabrication process.

Meetings are held before noon and in the evening. Sales, the Quality Assurance Department, and Logistics share information to make delivery arrangements.

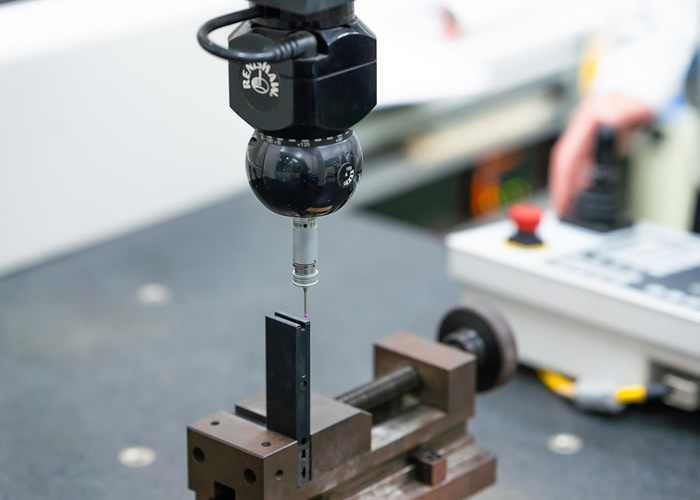

The quality control department in the head office inspects every single prototype part from various angles over several days.