Reliable Technology and Reliable Products

Yahagi Industries' mission is to create products quickly that are environmentally friendly, with safety as our number one priority.

We provide prototypes and mass production with an agility and added value that other companies cannot.

This is achieved through over 70 years of technological experience, a variety of introduced machinery and a “Let’s make this happen” attitude. We will also utilize human hands from time to time. We are proud of having been involved in the majority of Toyota’s underbody car prototypes, which is a testament to our technology and reliability. The fact that all manufacturing processes are completed at our three plants, in our headquarters, also Mifune, and Fujioka is a major feature Yahagi Industries are proud of.

CONCEPT

Yahagi Industries’ Manufacturing Concept

What is Yahagi Industries’

SLIM TECHNOLOGY?

SAFETY,SPEED,SHORT PROCESS

Technology and skills that enable work to be done safely, quickly, in short processes, and at high speed.

SMALL VOLUME

Technology and skills that allow for the flexible production of a wide variety of products in small quantities.

LOW COST

Technology and skills to achieve competitive low costs.

LIGHT WEIGHT

Technology and skills that realize resource saving and weight reduced environmentally friendly products.

MULTI PRODUCTS

Technology and skills to handle not only existing products, but a wide range of other products.

Plant Introduction

Yahagi Industries utilizes technology cultivated over many years to handle a wide range of needs, from prototyping and modifying of car bodies and parts, to manufacturing small-scale mass-produced parts. The roles, facilities, and manufacturing details of each plant are introduced here.

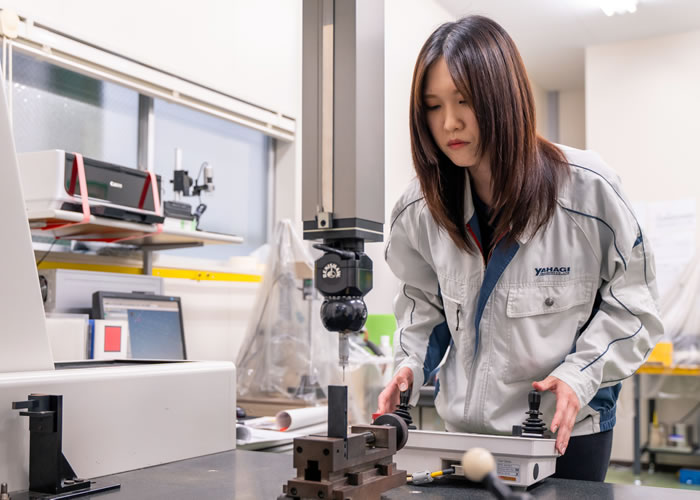

Safety is where our technology needs to shine the most. The prime consideration is precision. To achieve this goal, we manufacture and process parts and jigs using not only computers and data, but the skilled hands and eyes of experienced craftsmen. We pursue the finest quality, sometimes down to the 1/1000 mm level, and will spend several days carefully scrutinizing and controlling new parts. Yahagi Industries continues striving to improve precision and quality, daily.

Quality Management